- Lab Services

- Surface Roughness & 3D Topography

- Chemical

- Color Measurement

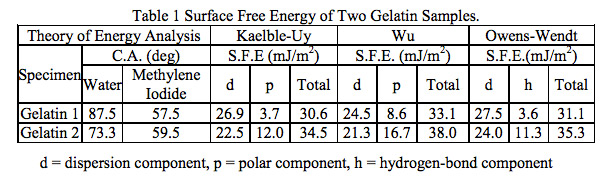

- Contact Angle

- Gloss Measurement

- Liquids

- Mechanical

- Abrasion

- Contact Stylus Surface Roughness Analysis

- Depth Profiling

- Express Property Mapping through Accelerated Nanoindentation

- Macroscratch

- Microindentation

- Microscratch

- Modulus Mapping

- NanoDMA

- Nanoindentation

- Nanoscratch

- Rheology

- Scratch Testing ISO 1518

- Shore A and Shore D Hardness

- Universal Testing Machine

- Metallurgy

- Microscopy

- Particle Size

- Peel Strength

- Pore Size

- Technical Consulting

- Thermal

- Tribological

- X-Ray Diffraction

- Zeta Potential

- Products

- Industries

- Resources

- About Us

- Testimonials

- Contact Us